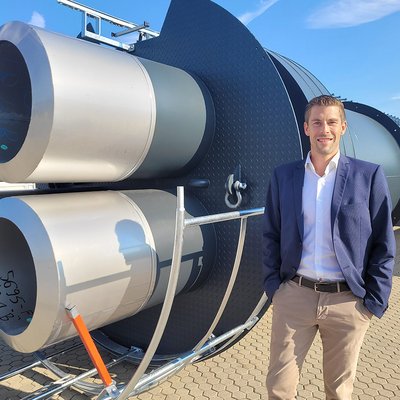

Flue gas duct / components

Flue gas ducts serve as a robust and secure connection solution between the boiler/engine outlet and the chimney inlet, and typically require detailed planning in coordination with the construction management, as well as on-site measurements.

Depending on the application and customer requirements, they are designed as a modular element system or fully welded/flanged.

Both solutions offer distinct advantages:

| Welded | Element construction |

|---|---|

| Completely gas-tight (H0) | Quick assembly through plug connection |

| Few attachment points required | Double-walled including insulation and cladding |

| High pressures possible > 10.000 Pa | No compensators required |

| Custom-made | Fast delivery through standard components |

| Dimensions up to Ø 2500 mm | Dimensions up to Ø 1200 mm |

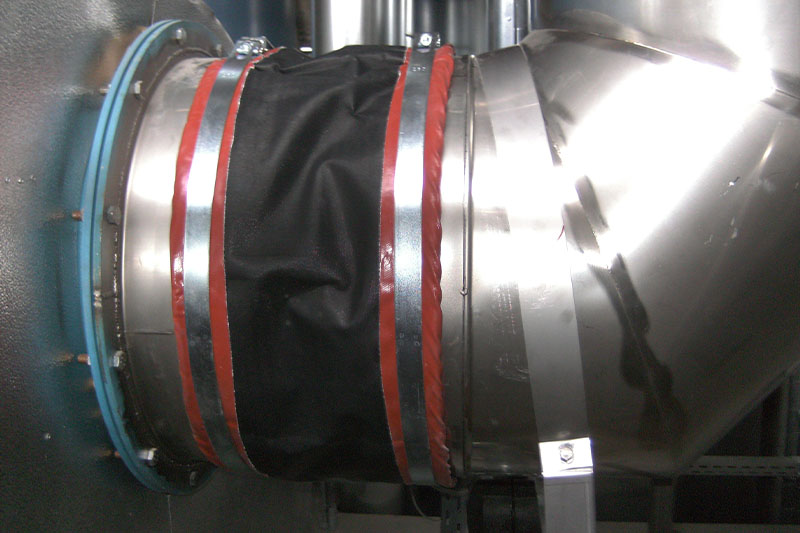

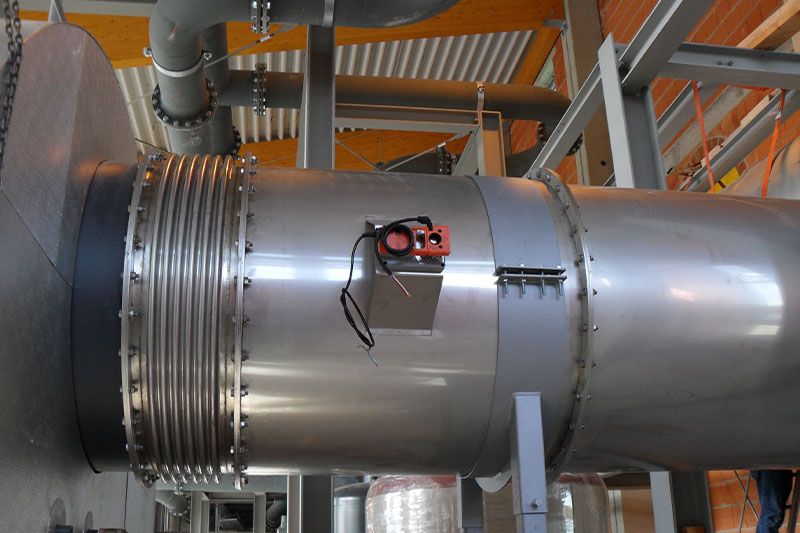

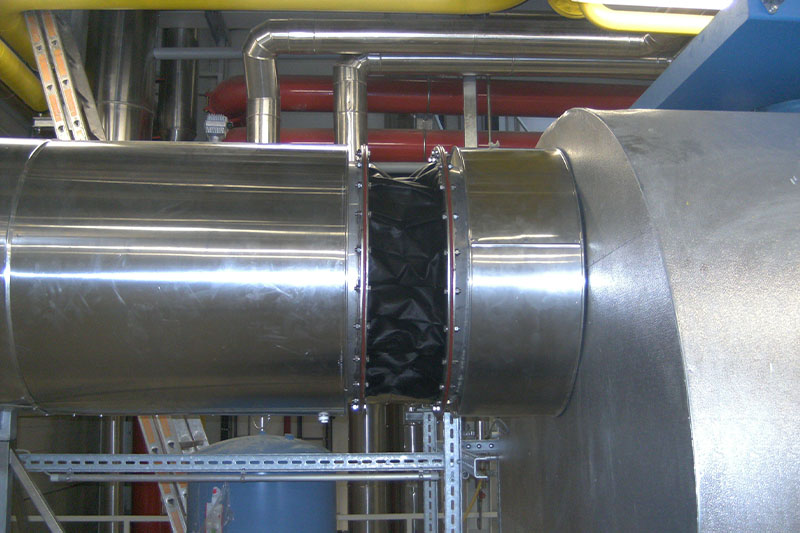

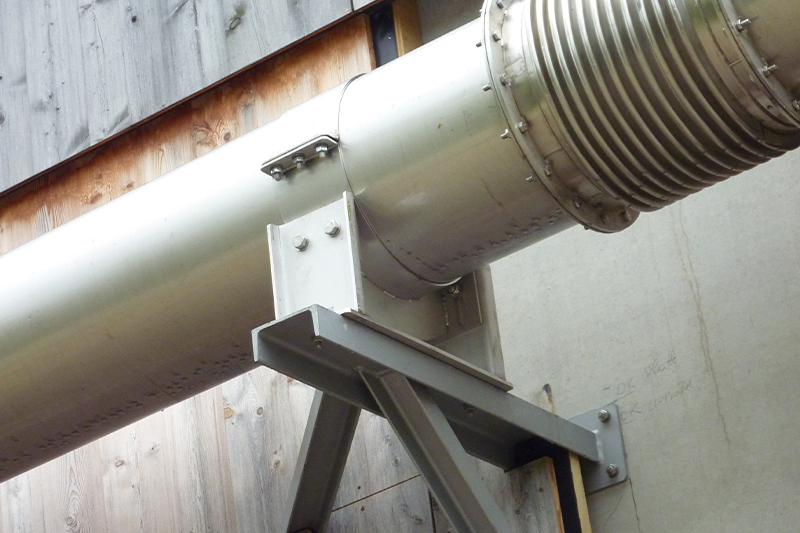

The planning of compensators, flue gas dampers, and steel construction supports is handled by our experienced project managers, who are specially trained in this area.

As part of our "All-in-One Package," we are also happy to take care of manufacturing, transport to the construction site, and on-site installation.