CHP / CCHP systems

Simple solution with double benefits

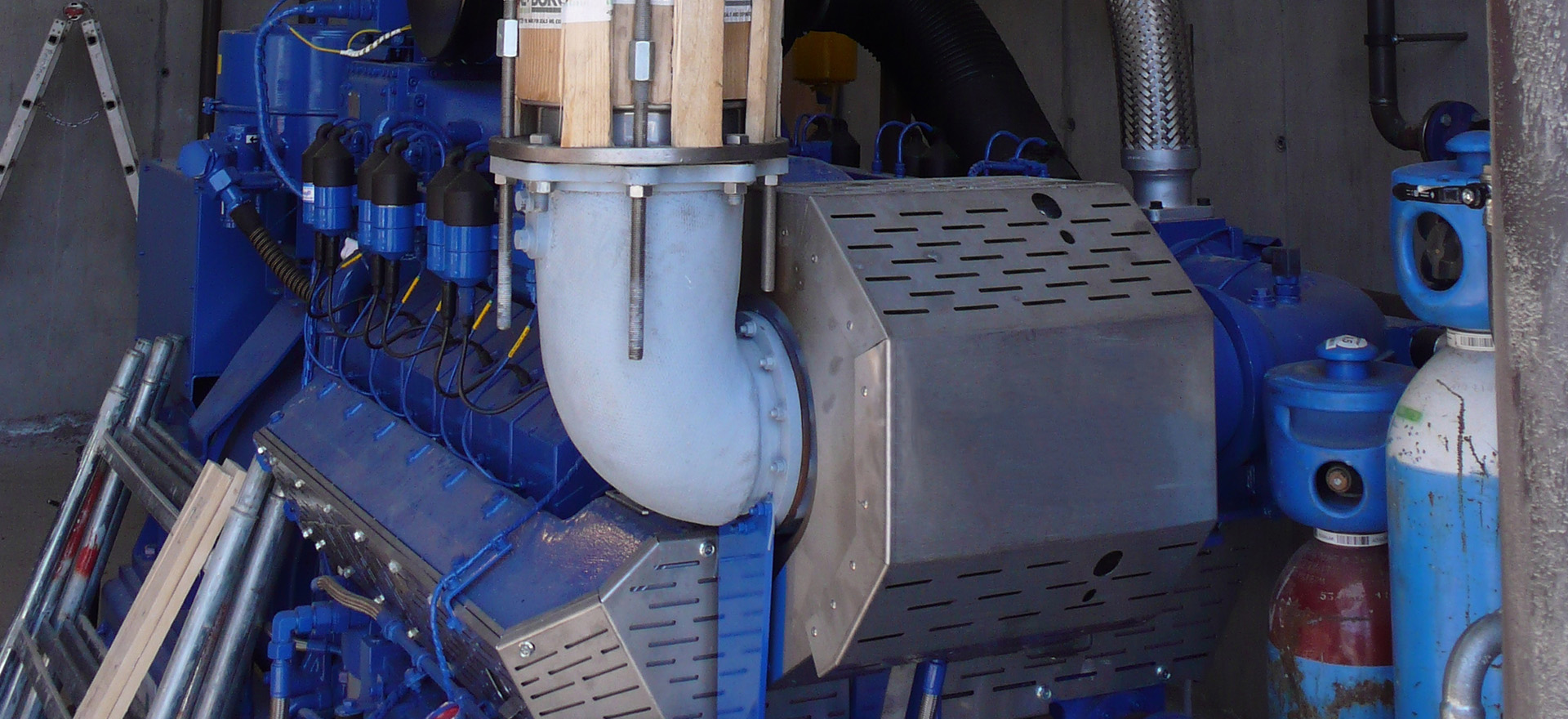

Decentralized combined heat and power (CHP) plants and cogeneration (CCHP) systems make a valuable contribution to a successful energy transition.

Based on the principle of combined heat and power (CHP), they generate electrical energy while also utilizing the released heat on-site for purposes such as heating or industrial process heat.

In this way, they achieve very high efficiencies and, in the ideal case, can recover more than 90% of the primary energy used.

Fuels for CHP

We offer tailored exhaust systems for CHP plants. Supported by the planning expertise of Jeremias experts, we provide the properly dimensioned solution for CHP systems in all power ranges.

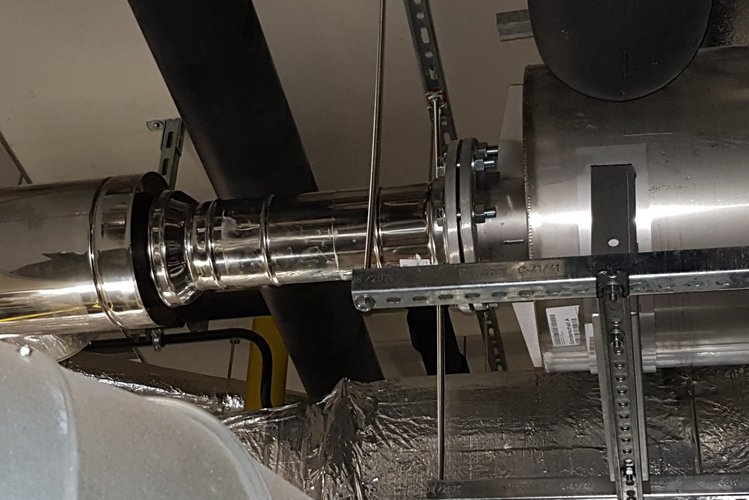

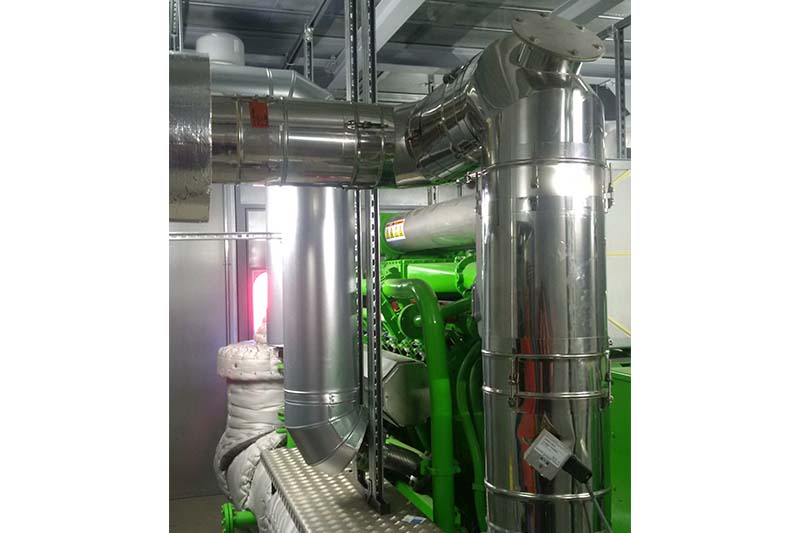

For smaller power plants, the EW-PPS is an especially cost-effective polypropylene exhaust system. It efficiently handles applications in the temperature range up to 100°C in continuous operation. The single-wall stainless steel system EW-KL with a metallic conical flange seal is designed for exhaust gas temperatures up to 600°C. More demanding applications in the same temperature range can be implemented with the double-walled, mineral-insulated exhaust system DW-KL. Additionally, the special DW-KL connection pipe DW-KH ensures a power- and form-locking connection. This enables pressure-tight pipelines even in unfavorable installation situations.

All four Jeremias CHP exhaust systems are designed for a pressure of up to 5,000 Pascals, meeting the highest temperature and pressure resistance requirements. As a chimney kit, they are also much easier and quicker to install compared to welded alternatives on-site.

Also, find out more about our extensive range of