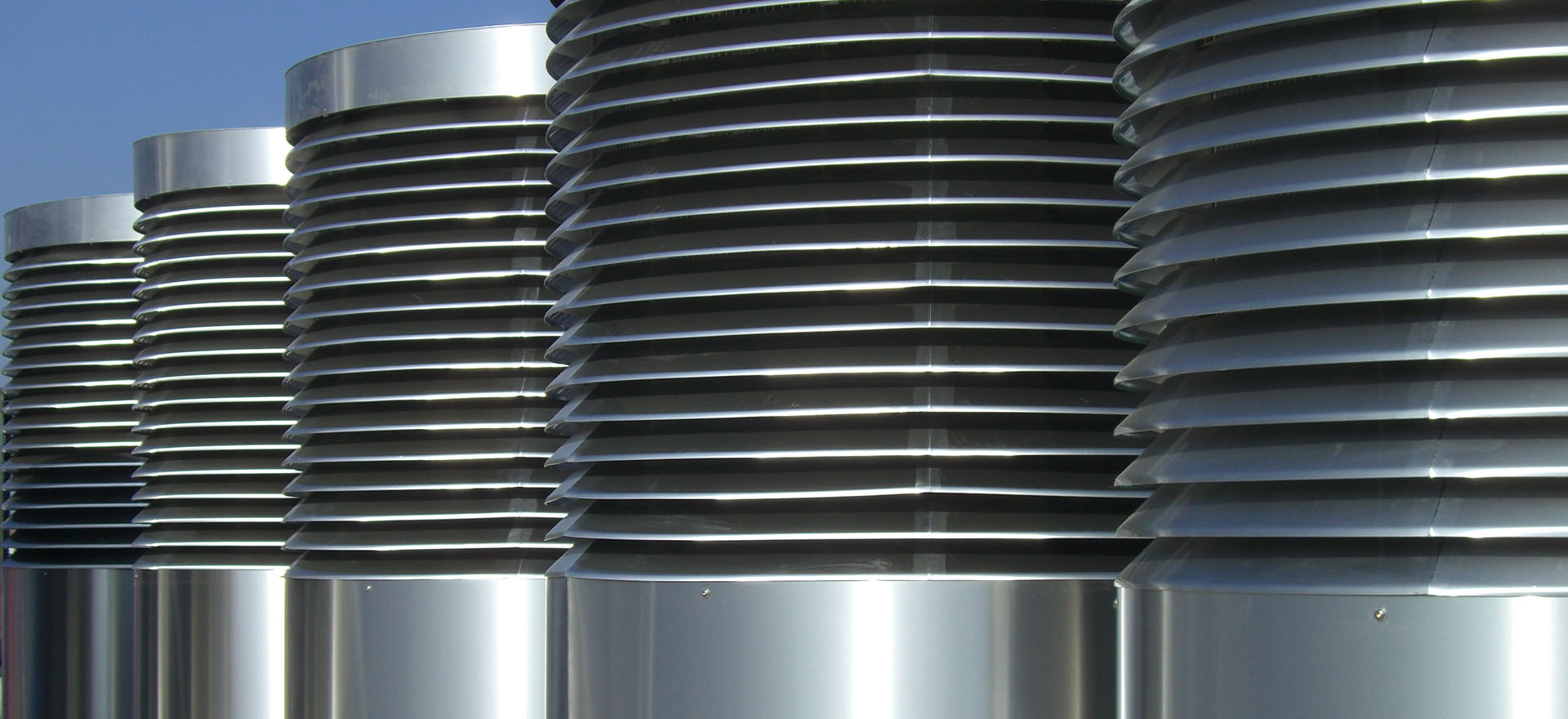

Ventilation towers

High Performance and Innovative Design

Jeremias ventilation systems combine high functionality and elegant design in an impressive way.

As a freestanding, single-walled supply/exhaust chimney, the "FSC" is used in air conditioning and ventilation technology. The visible, statically load-bearing pipe also serves as the medium-carrying system.

As part of modern building complexes, supply/exhaust chimneys must not only be functionally designed for the specific application but also meet the highest aesthetic standards. With their often individually refined, polished, or painted stainless steel surface, our ventilation towers are always an eye-catching feature on building facades, in courtyards, and even on industrial roofs.

Special customer requirements are considered right from the planning stage.

Whether it's an intake tower with louvered hoods in various shapes, an exhaust tower as a cost-effective alternative to the FSA chimney for low-emission exhaust, or a combined supply/exhaust tower – Jeremias designs systems in a project-specific manner, taking into account flow resistance and airflow noise, and with high professionalism.

Thanks to our decades of experience in processing stainless steel of all wall thicknesses, we can guarantee ventilation towers of premium quality.