Accessories for industrial chimneys

Useful additions and individually selectable additional components

Work Platforms / Inspection Platforms

Work platforms for inspection, measurement, cleaning, walking, or assembly are manufactured in both rectangular and circular designs with 135°, 180°, 270°, or 360° configurations.

All versions are equipped with handrails, knee rails, and toe boards. A grating surface ensures the drainage of rainwater and simultaneously prevents the formation of ice.

All components are hot-dip galvanized or made of stainless steel and can be painted in chimney or special colors upon request.

Ladder

A ladder is installed at the exhaust system’s outlet in accordance with the UVV (German accident prevention regulation) on the support pipe (usually on the outside) when there is an existing chimney sweeping duty.

In the case of a so-called single-rail ladder, a guide or fall protection rail, welded firmly to the rungs, is integrated in the middle. The person climbing the ladder secures themselves using a runner and harness on this rail. The single-rail ladder is fixed to the chimney every 1.4 meters with hot-dip galvanized, painted brackets. Every 10 meters, a fold-out rest platform is provided, and the final platform is located 1.2 meters below the outlet. Alternatively, the climb can also be done using a double-rail ladder with back protection. In this version, the use of a runner and harness can be omitted due to continuous back protection. Instead of a fold-out platform, a changeover is required every 6-10 meters to ensure a safe climb.

Made of galvanized steel or stainless steel, ladders are highly corrosion-resistant, both in the exhaust plume area and in chemical plants or near the sea.

Flue terminal

The flue terminal cap, typically made of stainless steel (the same material as the inner pipe), serves to cover the insulation and acts as rain protection for the ventilation between the inner and outer pipes.

By being exclusively fixed to the inner pipe, the cap ensures the free expansion of the inner flue pipe upwards. The height of the cap is determined based on the exhaust gas temperature and the chimney height, as these two factors are crucial for expansion.

Wall mounting

A steel structure, designed according to static calculations to absorb horizontal forces, is fixed to the building at a defined location. This can be positioned on walls, steel beams, or ceilings. The foundation of such a mounting method is the absorption of static and dynamic loads at the connection point.

When using a wall connection, almost all horizontal loads are transferred to the connection point. As a result, the installation of an anchor basket is not required, meaning that the foundation only needs to support the weight force, making it as small as possible.

Lightning Protection

Lightning strikes are directed to a building-installed lightning rod via the lightning protection tab, which is mounted at the base of the chimney. The lightning protection connection must ensure the grounding of the chimney system. The connection is made on-site by a specialized lightning protection company. For chimneys over 20 meters in height, two grounding connections must be provided.

If the freestanding chimney is partially inside a building, the chimney must be connected to the building’s external lightning protection, if available, above the roof.

An insulated lightning protection system is installed at a distance, meaning it is insulated from the object being protected. The capturing system, typically consisting of three capture rods, creates a protection zone in the form of a circular cone with a vertical axis around the tip of the capture rod. In this protection zone, direct lightning strikes are prevented, thus protecting the chimney outlet from a strike. The chimney system and the connected flue are therefore completely protected from lightning strikes.

Swivel Arm

A lifting crane with a manual or motorized winch is used for the easy transport of heavy measuring equipment or accessories, significantly reducing the risk of accidents when ascending to the measurement/inspection point.

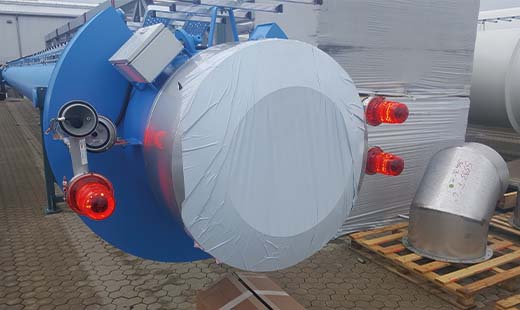

Obstacle Lighting

Obstacle lighting is used to mark the chimney outlet and is specifically required in the flight paths of both public and private airports. It may also be required at landing sites for hospitals.

The power supply to the halogen or LED lights (with lifespans of 4000 or 10,000 operating hours) at the outlet is provided through cable ducts inside or on the outside of the chimney support pipe.

In addition to lighting, a warning coating in the form of signal stripes or other markings may be applied to enhance visibility during the day.

Special Coatings

Special coatings can be used for daytime identification, as a distinguishing feature, such as by placing a company logo, or simply to better blend the chimney into its surroundings. These coatings are applied in multiple painting steps using stencils, allowing for easy execution in multiple colors. This offers limitless possibilities for creativity!

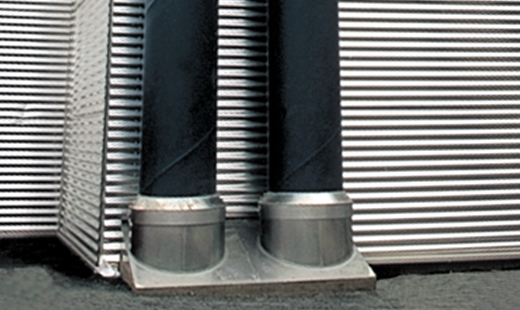

Roof Sealing

A well-designed sealing system on the chimney casing is essential for properly integrating a chimney system into a roof penetration. A special fitting made of a base plate and sleeve pipe is used to close the penetration. To accommodate chimney movements, the weather collar is attached independently to the chimney casing. The weather collar extends over the sleeve pipe of the fitting, creating a rainproof system.