Condensing technology

Energy-efficient and environmentally friendly

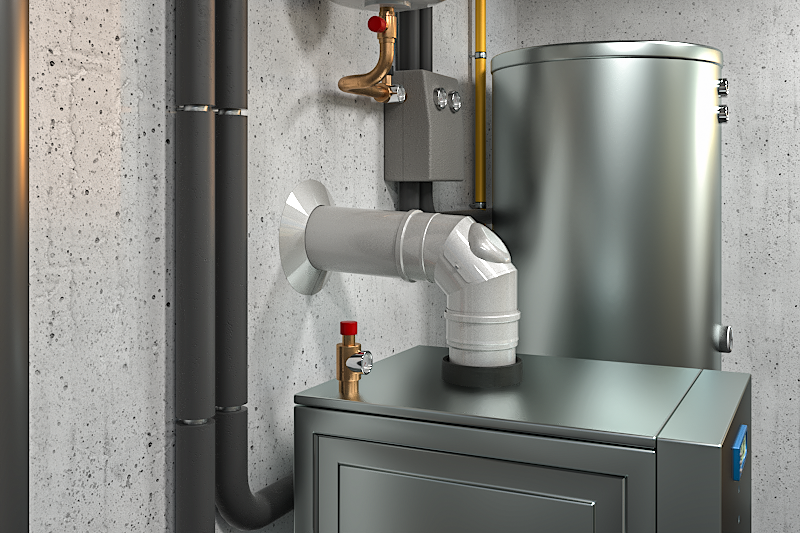

Condensing technology is one of the most efficient, environmentally friendly, and technically advanced heating systems in the field of heating appliances. Through a downstream heat exchanger, the hot exhaust gases are cooled until the water vapor contained within them condenses. In this process, the heat energy stored in the steam is not wasted, but can instead be actively utilized.

By cooling the gases, the exhaust gases are released relatively cool, typically in the range of 40°C to 50°C. This temperature can be higher depending on the heating system used and the operating conditions, such as in domestic hot water heating.

In contrast to conventional boilers, this process can save up to 10% of energy, and thus heating costs. This energy savings can be significantly increased when additional renovation measures are carried out on a building, such as replacing old windows or adding external thermal insulation.

The resulting condensate can be neutralized depending on the pH level and the fuel used, and then discharged into the sewage system.

Function of the condensing device

The combustion of a fuel generates heat energy, which is made usable in heating boilers through heat exchangers and is available as hot heating flow.

In conventional heating boilers, this conversion takes place directly in the boiler, where the exhaust system inside the boiler is designed so that a large portion of the energy contained in the hot exhaust gases is transferred to a heat carrier, such as water, and thus can be used.

However, these heating appliances are not designed to operate with low exhaust temperatures, which is why they usually operate in a range of over 120°C, and the exhaust gases are vented through the naturally occurring negative pressure.

The residual heat still contained in the combustion gases, in the form of hot water vapor, cannot be further extracted in such systems and is therefore wasted into the environment.

For this reason, a heat exchanger can still be added in conventional boilers.

Advantages of condensing technology

Thanks to an integrated heat exchanger, the heat energy stored in the hot exhaust gases can be better utilized. This significantly increases the efficiency of a condensing heating appliance compared to a conventional heating appliance. This not only results in energy savings but also lower heating costs, especially when combined with the modernization of the heating system and additional renovation measures.

In condensing devices, natural discharge of the exhaust gases, as is the case with conventional heating boilers, can no longer occur without issues, as the necessary temperature difference to the outside air is no longer large enough.

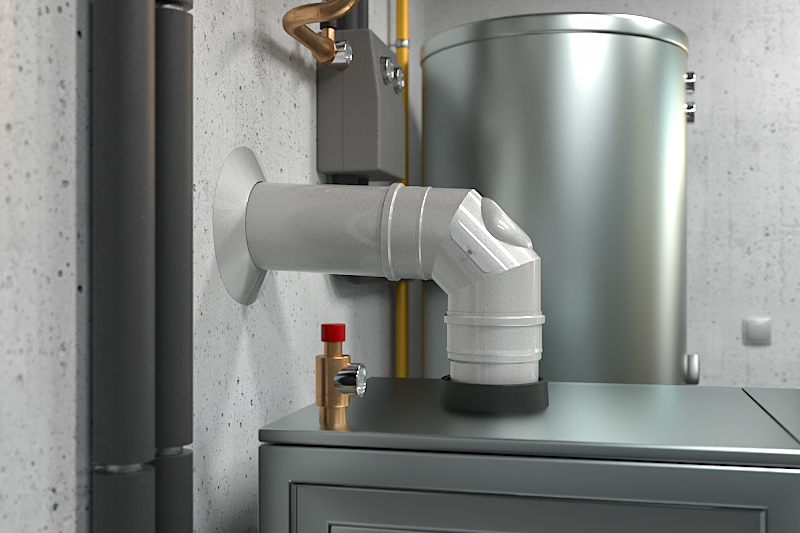

Therefore, these systems are equipped with a blower inside that pushes the exhaust gases with a pressure of up to 200 Pascals (Pa) through the exhaust system to the outside.

The exhaust system or chimney must be designed to handle the resulting overpressure. This is the case if they are labeled with the pressure class "P1."

Additionally, it is important to use a moisture-resistant and sufficiently corrosion-resistant system, as the condensate may contain components that could attack inferior or unsuitable materials.

When a condensing appliance is used for solid fuels, such as wood pellets, the components of the exhaust system must be pressure-tight and also resistant to soot fires.