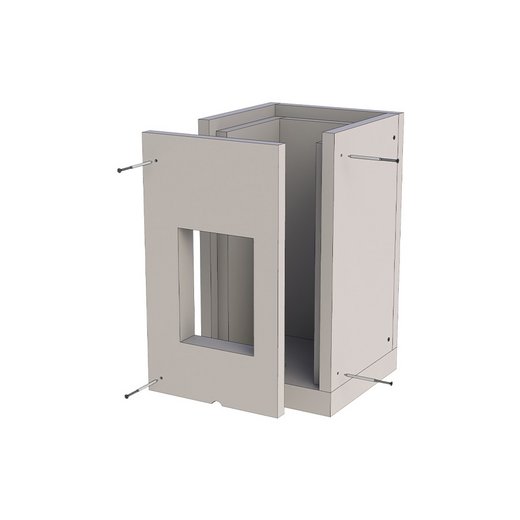

FURADO-A

Lightweight Chimney System for Oil and Gas Heating Appliances

The lightweight shaft system FURADO-A, consisting of calcium silicate fire protection panels, Jeremias inner pipes from the EW-KL, EW-AL-BI, EW-PPS, or EW-PP-FLEX systems, and 25 mm thick insulation shells depending on the exhaust temperature, is used in connection with heating appliances powered by oil or gas. The roof installation can be carried out using either a shaft and cladding or stainless steel pipes.

Alternatively, the FURADO-A can also be used as an installation shaft for receiving CE-certified inner pipes and, depending on the exhaust temperature, with 25 mm insulation shells.

SYSTEM_DETAIL_ICONS