Before Purchasing a Chimney – What to Consider

Heating systems and exhaust systems form a unified system and must be perfectly coordinated for efficient and safe operation. Before choosing the appropriate chimney or exhaust pipe, several factors need to be considered.

Fuel

A key criterion when selecting the appropriate exhaust system is the type of fuel used for heating. Fuels can be classified according to their origin.

Fossil fuels are derived from plants and animals that died millions of years ago, primarily consisting of carbon and hydrogen. They represent a finite energy source and release large amounts of stored CO2 when burned. Fossil fuels include coal, oil, and natural gas.

Biomass, on the other hand, refers to renewable fuels that have actively participated in the carbon cycle before use, which is why they are considered "CO2-neutral." Common examples of biomass include wood (logs, pellets, wood chips), specially cultivated plants such as corn, grains, and elephant grass, as well as all kinds of organic waste.

In 2021, nearly 50% of heating in Germany was powered by gas, followed by heating oil at 25%. Gas and oil thus account for about three-quarters of heating energy, while solid fuels like logs, wood pellets, or coal contribute just over 6%.

Exhaust Temperature

The choice of fuel has a significant impact on exhaust temperature, which in turn influences the selection of the appropriate exhaust system.

Gas or oil heating systems operate with much lower exhaust temperatures compared to combustion systems using solid fuels such as wood or coal. This is especially true for gas/oil condensing units, which use energy very efficiently, resulting in even lower exhaust temperatures.

Masonry chimneys or traditional concrete chimneys require a high exhaust temperature of 180°C – 200°C at the chimney inlet to prevent condensation inside the chimney, which could cause moisture buildup and lead to long-term issues such as creosote buildup. These are therefore only suitable for dry operation, i.e., for solid fuels with sufficiently high exhaust temperatures.

Jeremias stainless steel chimneys are also suitable for high exhaust temperatures, and thanks to moisture-resistant materials, they can also be used with modern condensing units, where exhaust temperatures often do not exceed 80°C and condensation in the chimney is even desirable (moist or condensing operation). The same applies to our plastic exhaust systems.

Pressure Tightness

The low exhaust temperatures of modern condensing heating units can sometimes hinder natural chimney draft, as cooler air rises more slowly than the warm exhaust gases from solid fuel heating appliances.

To ensure the proper expulsion of exhaust gases outdoors and maintain smooth combustion, most modern condensing units are equipped with an integrated fan. This supports the chimney effect and creates positive pressure in the exhaust pipe, necessitating the use of pressure-tight exhaust systems.

Soot Fire Resistance

Burning solid fuels produces soot, which settles in the chimney. When dry firewood is used, the soot deposited in the exhaust pipe can be easily removed by a chimney sweep.

However, using too damp or unsuitable fuel results in wet soot accumulating on the chimney walls. This does not pose an immediate danger due to its moisture content but is often not fully removable with standard cleaning tools. As the soot hardens with increasing exhaust temperature, it becomes highly flammable. Normal sparks from the combustion process can then ignite a soot fire, causing flames at the top of the chimney and temperatures exceeding 1000°C.

Chimneys designed for dry operation with solid fuels must withstand such soot fires without damage, such as cracks, otherwise, they would become unusable.

Information about soot fire resistance is provided by the classification of the exhaust system.

All Jeremias systems that are approved for dry operation are either soot fire-resistant (marked "Gxx") or moisture-resistant (marked "Oxx") if used in condensing operation.

Non-soot fire-resistant exhaust systems, such as plastic systems, may only be connected to devices that use liquid or gaseous fuels in wet operation.

A special feature of our condensate-acid-resistant SILVER systems is that they can continue to operate in a condensing mode even after a soot fire, making them both moisture-resistant and soot fire-resistant.

Exhaust System Diameter

The cooler exhaust temperatures today would not be sufficient to safely expel exhaust gases outdoors in the traditionally large domestic chimneys, potentially leading to incomplete combustion, smoke leakage into the building, or risk of chimney fouling.

To maintain proper chimney draft, modern heating appliances with lower exhaust temperatures require smaller chimney diameters. These should be determined by a professional through a cross-sectional calculation tailored to the specific heating unit.

Chimney Height

Chimney height also significantly affects chimney draft. Generally, the taller the chimney, the better the draft.

Minimum height requirements for chimneys are defined in regional regulations for oil and gas heating appliances and nationwide for solid fuels in the Federal Emission Protection Ordinance (BImSchV).

With the new flue gas discharge conditions effective from January 1, 2022, under §19 (1) of the 1st BImSchV, the chimney outlet of newly installed small and medium solid fuel appliances with less than 1 MW output must be close to the roof ridge, improving air quality in residential areas, particularly reducing fine dust, odors, and smoke.

The minimum chimney height according to §19 (1) BImSchV must take into account factors such as the roof shape and slope, the distance from neighboring buildings, and the appliance's output. In general, the chimney must be higher the further it is from the ridge (maximum ¼ of the building width).

Alternatively, the required chimney height can be calculated using VDI 3781 Sheet 4.

All information on the topic can be found in our

special feature „New Discharge Conditions“

Room Air-Dependent or Room Air-Independent Operation

Heating appliances can draw the necessary combustion air either from the living space (room air-dependent) or from an external air supply duct (room air-independent).

The advantage of room air-independent operation is that the usual requirements for the minimum air volume of the room can be omitted, and simultaneous operation of the heating appliance and ventilation or exhaust systems can proceed without restrictions.

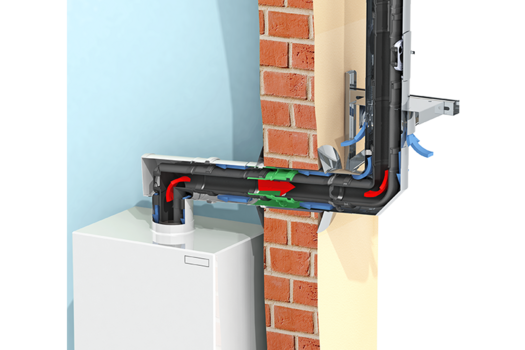

Fresh air can be supplied either via a separate intake system or through a concentric exhaust system (also known as a LAS chimney), where the intake air is directed to the appliance through the annular gap between the exhaust pipe and outer pipe.

Acceptance

When installing a heating system with an exhaust system, several important regulations must be observed. For example, the minimum distances to combustible materials must be clearly defined and adhered to. Additionally, it must be ensured that the exhaust system is compatible with the heating system, no exhaust gases can enter the living space, oxygen supply is ensured, chimney placement and height requirements are met, and many more.

Therefore, it is advisable to consult the responsible district chimney sweep during the planning phase. They must approve the entire system before the first operation and can offer valuable installation tips. The installation itself should ideally be carried out by a qualified specialist.