Exhaust Dampers

Helps save energy and prevents the backflow of flue gases

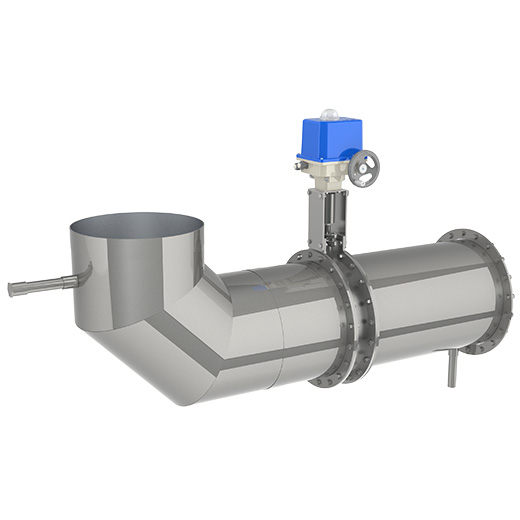

Exhaust dampers are installed in the connecting pipe between the boiler and the chimney, closing the flue gas path to the chimney when it is no longer needed.

This prevents the heat generator and the room from cooling down and significantly contributes to energy savings. Additionally, they prevent the backflow of flue gases from other connected heating systems into the room, especially in cascade systems, and provide some sound insulation in multi-flue chimneys.

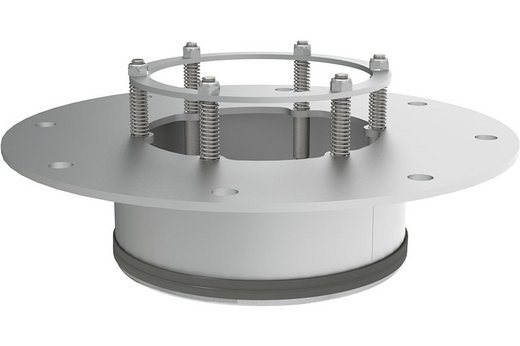

We offer both manually operated exhaust dampers and motorized dampers that are automatically controlled by the burner.

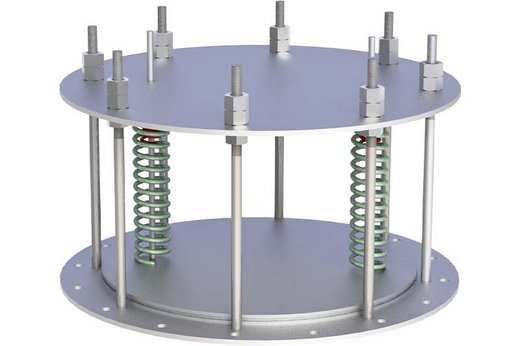

A special case are implosion dampers (Joukowski dampers) and explosion dampers (pressure relief dampers), which balance unwanted pressure fluctuations in the flue gas line.